This blog post is part of a series summarising my PhD project and the steps to complete my degree. The information in this blog post outlines the introductory chapter of my thesis (downloadable here). Information includes the motivation, areas of investigation and summary of key contributions.

Textile Waste

The textile industry is one of the significant contributors to environmental damage in the 21st century. The disposal of textiles, especially clothing, is a significant issue due to the fast-fashion practices that have become common. When clothes are disposed of in landfills, it can cause considerable harm—the decomposition of clothing releases methane. This greenhouse gas contributes to climate change. Furthermore, toxic chemicals such as dye can seep into the soil, causing environmental pollution. Some experts suggest recycling discarded clothing through chemical processes to combat these issues and create new materials like lyocell. However, these methods are not widely used as sorting discarded clothing for appropriate recycling processes is labour-intensive, and the produced materials from upcycling cannot justify the cost of sorting and preparing post-consumer clothing.

Given these difficulties, my thesis was inspired by the challenges within textile recycling. I investigated the limitations robots face in deformable manipulation and whether feasible solutions existed for textile waste management solutions. The resultant research from my thesis created a unique robot gripper that remained a simple mechanical device but captured the necessary dexterous skills to sort textile waste. In addition, reinforcement learning algorithms were deployed onto the gripper to learn grasping motions that leverage the environment to improve grasp success upon flattened garments.

A textile sorting facility in Australia.

The Environmental Impact

Environmental damage occurs at many steps in the fabric production and disposal cycle, as detailed by Pensupa et al. [Pensupa 17]. Their overview of the topic provides an in-depth description of the clothing industry’s devastating environmental impact and sustainability trends. The ecological damage of the clothing industry can be attributed to both physical waste and chemical byproducts, primarily wastewater, generated during manufacturing. Despite the organic components in fabrics, waste objects decompose slowly, taking up to twenty years, depending on the composition, to biodegrade [Pensupa 17]. Synthetic fibres are a significant contributor to increased decomposition time.

Additionally, decomposing clothing in landfills can release toxic gases that contribute to CO2 emissions. Each stage of a garment’s commercial life cycle presents an opportunity for possible polluting events [Claudio 07]. Claudio also describes the ecological impact of textile manufacturing and the potential benefits of recycling. The production process of synthetic fibres can be an emission-intensive process requiring crude oil.

Alternatively, manufacturing natural fibres, with cotton being one of the most popular, can require enormous amounts of fresh water during production while also causing soil degradation and erosion. Clothing manufacturing can also damage the environment from the wastewater generated when garments undergo dyeing, rinsing, or chemical refinement. The fast-fashion and clothing industry has produced approximately 20% of the world’s industrial wastewater pollution, according to Kant [Kant 11]. Kant also describes the damaging impact of wastewater on the environment and infrastructure, including corrosion of irrigation frameworks, breakdown of drinking water supplies, and evaporated chemicals affecting the air quality in populated areas.

The Economic Landscape

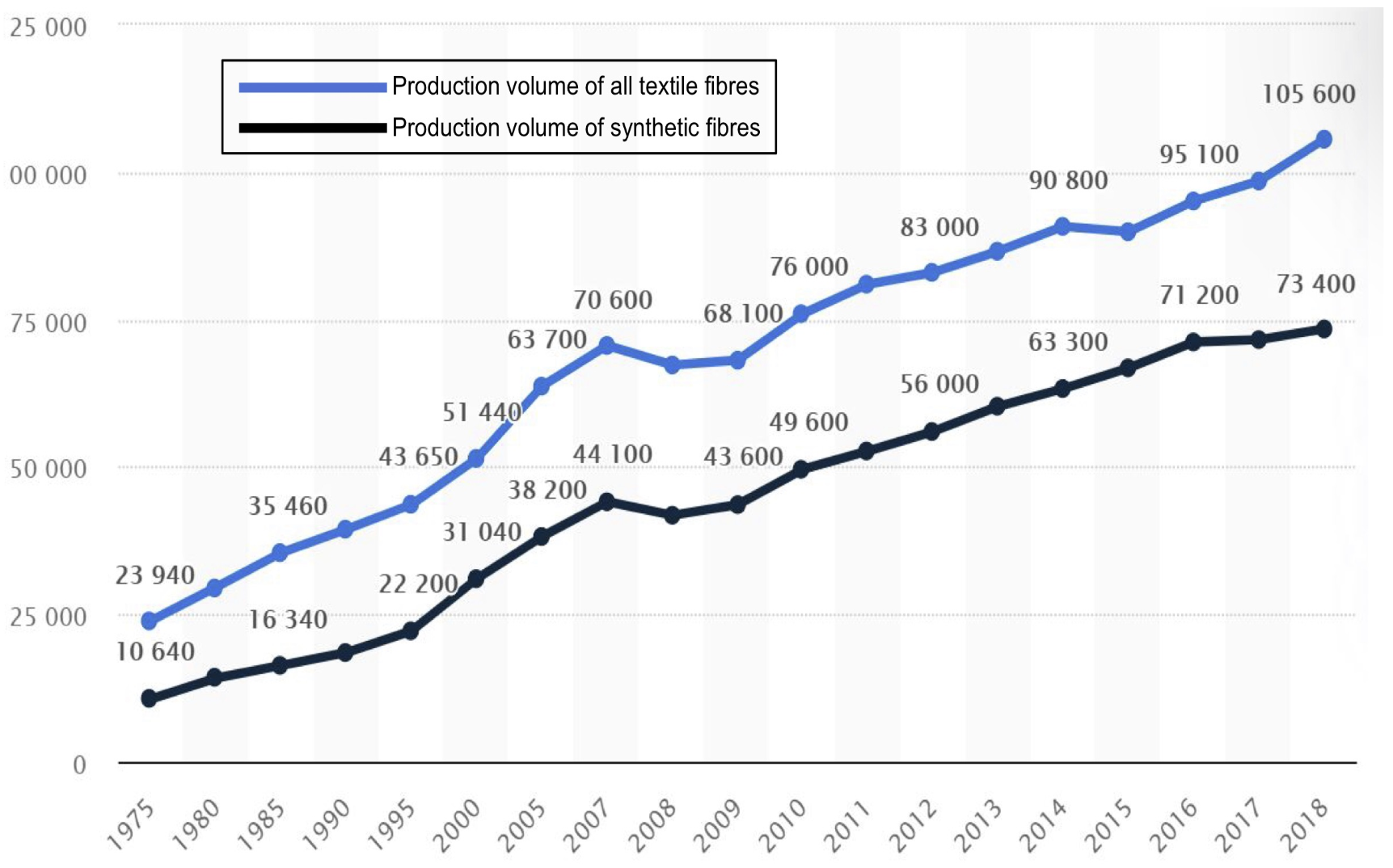

Physical textile waste can be classified as either pre-consumer or post-consumer. The former refers to waste from production, while the latter is generated after the product has been used. Due to increasing consumption, levels of post-consumer waste have risen. For instance, in 2009, 13 million tons of clothing were sent to landfills in the USA, with only 14.9% recycled [Joung 13]. According to an Environmental Protection Agency (EPA) report [EPA 21], the mass of textiles sent to landfills increased to approximately 17 million tons in 2018. Shui et al. [Shui 11] observed a consistent increase in global per capita consumption (PCC) of clothing from 3.7kg in 1950 to 10.4kg in 2008, with developed countries contributing significantly to the growth. However, in recent decades, the PCC of developing nations has been growing at a significantly higher rate. The demand for cheaper synthetic fibres has also increased due to the resources required to manufacture natural fibres. Approximately 76 million tons of textiles were produced globally in 2010, which increased to 106 million tons in 2018 (See image below).

Authors such as Bick et al. [Bick 18] and Niinimäki et al. [Niinimäki 20] have discussed how increased consumption and improved efficiency have led to lower pricing and a consistent consumer pattern known as “fast-fashion.” This business model has worsened environmental concerns and led to unsustainable production practices, posing a significant environmental threat. Niinimäki et al. [Niinimäki 20] also explain how the globalization of the textile industry contributes to pollution inequalities and consequences, with developing nations bearing the brunt of manufacturing byproducts. Additionally, developed nations often export their post-consumer textile waste to developing nations. However, this unsustainable practice is starting to fail, as nations refuse to import textile waste to protect their local economies.

A graph showing the rising prodcution textile fibres worldwide.

1This statistic comes from several IVC (Industrievereinigung Chemiefaser) chemical fiber industry updates hosted on the site Statista.

Source: https://www.statista.com/statistics/263154/worldwide-production-volume-of-textile-fibers-since-1975/.

Fast fashion also contributes to the issue of ‘deadstock’, which is a specific type of pre-consumer waste consisting of garments that are manufactured but remain unsold or unused. Typically, this waste is disposed of through incineration, which destroys the significant resources invested in manufacturing. Changing the current state of the textile industry involves complex and multifaceted efforts, requiring modifications to industry practices and consumer habits. Niinimäki et al. [Niinimäki 20] suggest that achieving long-term sustainability in the textile industry will necessitate a reevaluation of the fast fashion model. In the late 2010s and early 2020s, media outlets reported on the devastating impact of textile waste, including an article by Besser [Besser 21] that details the impact of textile exports to Ghana, where approximately 40% of clothing received is not wearable due to poor quality.

The World Bank provided 9.5 million EUR to construct the Kpone landfill in an effort to address Ghana’s increasing textile waste problem. However, the landfill was full after just five years of use. In 2019, the decomposing material caused a methane bubble, which eventually ignited and resulted in a fire that lasted 11 months. Despite these challenges, Ghana continues to receive approximately 15 million garments weekly, indicating that global demand for textiles has not diminished. Elsewhere, Siegle [Siegle 19] outlines the unethical practices of the fast-fashion industry, including misrepresenting sustainability efforts and maintaining poor working conditions in developing nations. Siegle specifically references the collapse of the Rana Plaza complex in Bangladesh, an event that resulted in the tragic deaths of over 1000 workers. This highlights the widespread issues in textile manufacturing and the need for immediate attention to address poor industry practices with global impact.

Addressing the Issue

Existing Textile Recycling Approaches

Various strategies have been proposed to address the environmental impact of textiles in landfills. Zamani et al. [Zamani 15] conducted a case study on Swedish textile recycling practices, including energy recovery (incineration), material reuse, and chemical recycling. Incineration, a widely used method, involves burning textiles at high temperatures to produce energy, typically from steam to power generators. However, as Zamani et al. [Zamani 15] highlighted, this process results in emissions. It is considered a potential contributor to global warming. Pensupa et al. [Pensupa 17] also discussed the emissions and leachate associated with incineration.

Material reuse is an alternative to keep clothing out of landfills, involving the resale or repurposing post-consumer waste. According to Pensupa et al. [Pensupa 17], while these approaches do exist, repurposing is only a tiny part of what happens to textile waste. Zamani et al. [Zamani 15] explain that material reuse typically only applies to specific markets and depends on the collected material’s quality and the reuse demand. Additionally, chemical recycling processes offer another way to divert textile waste from landfills. Zamani et al. [Zamani 15] discuss separating cellulose from polyester using NMMO (N-Methylmorpholine N-oxide) solvent and the processes involved in polyester recycling. The initial step in recycling polyester is manually separating pure polyester garments from mixed or cellulose textile waste. Pensupa et al. [Pensupa 17] further elaborate on these techniques with a detailed discussion of various chemical-based fabric waste valorisation processes.

Using recycled cotton instead of virgin material can lead to significant water savings, with potential savings of up to 20,000 litres per kilogram of cotton grown, as discussed by Claudio [Claudio 07]. Pensupa et al. [Pensupa 17] highlighted the challenges in current textile recycling methods, emphasising the labour-intensive process of sorting fabric waste by size, composition, and fibre type. This task is further complicated when dealing with traditional waste streams [Wang 10]. Furthermore, Zamani et al. [Zamani 15] pointed out that the variety of garment compositions to be recycled will significantly influence the structure of any recycling effort.

Heikkila et al. [Heikkila 19] have developed a recycling project that utilises near-infrared (NIR) technology to separate textile waste into four categories with 90% accuracy. However, implementing a collection and sorting system is crucial for large-scale recycling efforts. The high volume of textile waste makes manual sorting labour-intensive, expensive, and economically impractical. To address these challenges, implementing robots to assist in the sorting process could reduce costs and alleviate the limitations associated with manual labour. Furthermore, when I discussed some of the limitations experienced by existing recyclers in Australia, they mentioned that sorting by composition is essential, as well as by garment type, foreign objects, and colour.

Using Robots to Overcome Limitations

The key takeaway from all this information is that the recycling of different textile waste streams is limited due to the manual labour needed to sort clothing based on various criteria for the appropriate recycling process. These criteria include characteristics such as garment type, colour, composition, and subjective qualities such as ‘resellability’. Although some commercial efforts have been made to implement sorting systems, they are often limited to specific waste streams or polymers. Zamani et al. [Zamani 15] recognise that textile waste’s diverse compositions and colours can restrict commercial applications.

Furthermore, Wang [Wang 10] describes how targeting specific materials is a preferred commercial structure for recycling. Businesses can focus on specialised processes or recycling outcomes by targeting particular waste streams, such as uniforms for sports or educational institutes. Alternatively, they can target alternative textile items such as carpets. However, these endeavours still need to improve in terms of sorting capabilities. Discussions I had with Australian textile recycling companies while exploring the issue of textile waste revealed the difficulties commercial endeavours experience with diverse waste streams. They detailed how using human labour to sort textile waste is costly and puts labourers at risk of repetitive strain injuries.

The textile industry faces the challenge of adverse human responses to specific items within the textile waste, such as undergarments, which are considered unhygienic. As a result, companies tend to focus on the most profitable textile waste streams. Typically, the recycling process involves using human labour to sort clothing into broad categories based on the type of garment or colour. However, implementing robotic labour for the initial sorting step could enable recyclers to expand their recycling efforts to a broader range of waste streams, potentially leading to a more comprehensive and efficient recycling process.

The vision that inspired my thesis was to empower robots to carry out the laborious, unhygenic, and repetitive tasks in the recycling process. This would involve robotic systems working alongside humans to improve the sorting process and move textile waste management closer to a circular economic model.

A cute picture of WALL-E trying to solve the problem.

Identifying an Area of Research

Manipulating textiles with robots is difficult because fabric behaves uniquely due to its anisotropic nature and non-linear mechanical response. Our discarded clothing comes in various colours, shapes, forms, and textures, making physical manipulation and visual interpretation complex and multifaceted tasks. Therefore, my thesis aimed to enhance robotic systems’ fabric-handling capabilities, acknowledging that clothing may have complex configurations requiring dexterous manipulation capabilities, and handling garments may demand a different set of intrinsic dexterous skills compared to rigid objects. I won’t place the literature review of my thesis here; you can always refer to the 300-page document for the specific limitations of existing robotic systems.

However, as I looked into previous approaches towards robotic fabric manipulation, a common theme appeared, in which many authors observed the advanced dexterous capabilities of humans when manipulating fabric, especially the research projects involved in robotic gripper design. In addition, previous research-based grippers designed for fabric handling targeted specific manipulation pipelines, such as folding a shirt or grasping flattened material. These devices were often inspired by heuristic human observations rather than a comprehensive study into the skills needed for generalised garment handling. As a result, they can be limited in terms of dexterous skills or develop designs with complex features like retractiable fingertips or passive joints with compliant elements. Given these aspects, a gap in the research was an extensive exploration of human behaviour and morphology in a robotic manipulation context to establish a novel design.

The Conducted Research

I used these aspects from the literature to design and develop a unique robot gripper for autonomous fabric waste sorting applications, potentially offering a solution for textile recyclers’ intense waste sorting challenges. The thesis’s research focused on observing limitations within existing robot manipulators designed to handle textiles and creating a novel manipulator that improves upon the state-of-the-art of existing devices. Since humans currently remain the most effective at manipulating fabrics and other deformable objects, I incorporated skills and features derived from human-centric studies to inform the development of this robotic end-effector.

The resultant gripper is a straightforward mechanical system encompassing various dexterous capabilities for fabric pick-and-place applications. After developing a simulation and hardware prototype, I employed two off-policy reinforcement learning (RL) algorithms to train the device. This training enabled the gripper to execute grasps that exploit environmental constraints, a unique challenge in fabric manipulation. These contributions are detailed further below, highlighting the practical applications of the developed gripper.

- My thesis started by studying the limitations of previous manipulators and using human-centric elements to inspire a novel gripper design. This contribution has two primary aspects.

- The first proposes anthropomorphic hand-centric taxonomies specific to fabric manipulation to discover unique gaps in existing designs. These taxonomies are derived from existing research that uses neuroscientific definitions to inform robotic manipulation methods. This approach was the first hand-centric investigation into gripper design for the fabric manipulation domain and established a unique gripper design that overcame several limitations previous devices encountered.

- Additionally, this contribution validated observations from the taxonomy via a human observation study. Several participants manipulated clothing in an experiment that studied temporal aspects of manipulation under conditions where human participants were limited by the grasp configuration they were allowed to use. Such an experiment confirmed that the proposed gripper design would be sufficient for generalised pick-and-place textile manipulation.

- Next, I took the observations and inspired design from the previous contribution to develop a prototype alongside a simulation of the proposed gripper for textile pick-and-place applications. This process includes rigid-body kinematic and dynamic analyses to understand the system’s physical characteristics, fabrication, electronics development, and integration into a ROS framework for the Baxter Robot.

- The final investigation introduces a reinforcement learning reward system inspired by human behaviour observed in the literature. Previous research has shown how humans use the environment when grasping flat materials to improve grasp success. This contribution’s research enables two off-policy reinforcement learning algorithms to learn motions that utilize environmental constraints to improve robustness when grasping flattened garments. This novel data-driven approach required a reward function based on the characteristics of human manipulation. The development process involved creating a simulated environment for learning the desired behaviour. Afterwards, these learned policies were deployed directly to the hardware platform, followed by an evaluation in the real world.

Use this link to view the next post surrounding my PhD project. This post details studying human manipulation capabilities and previous gripper designs to inspire a unique manipulator design.

References

[Besser 21] Linton Besser. “Dead white man’s clothes: The dirty secret behind the world’s fashion addiction”, Aug 2021.

[Bick 18] Rachel Bick, Erika Halsey, and Christine C Ekenga. “The global environmental injustice of fast fashion”. Environmental Health, 17(1):1–4, 2018.

[Claudio 07] Luz Claudio. “Waste couture: Environmental impact of the clothing industry”, 2007.

[Joung 13] Hyun-Mee Joung and Haesun Park-Poaps. “Factors motivating and influencing clothing disposal behaviours”. International Journal of consumer studies, 37(1):105–111, 2013.

[Niinimäki 20] Kirsi Niinimäki, Greg Peters, Helena Dahlbo, Patsy Perry, Timo Rissanen, and Alison Gwilt. “The environmental price of fast fashion”. Nature Reviews Earth & Environment, 1(4):189–200, 2020.

[Pensupa 17] Nattha Pensupa, Shao-Yuan Leu, Yunzi Hu, Chenyu Du, Hao Liu, Houde Jing, Huaimin Wang, and Carol Sze Ki Lin. “Recent trends in sustainable textile waste recycling methods: Current situation and future prospects”. Chemistry and Chemical Technologies in Waste Valorization, pages 189–228, 2017.

[Siegle 19] Lucy Siegle. “Fast fashion is on the rampage, with the UK at the head of the charge”. The Guardian, Jun 2019.

[Shui 11] S Shui and A Plastina. “A summary of the world apparel fiber consumption survey 2005–2008”. Food and Agriculture Organization of the United Nation (FAO) and International Cotton Advisory Committee (ICAC), Washington, pages 1–11, 2011.

[Wang 10] Youjiang Wang. “Fiber and textile waste utilization”. Waste and Biomass Valorization, 1(1):135–143, 2010.

[Zamani 15] Bahareh Zamani, Magdalena Svanstrom, Gregory Peters, and Tomas Rydberg. “A carbon footprint of textile recycling: A case study in Sweden”. Journal of industrial ecology, 19(4):676–687, 2015.